|

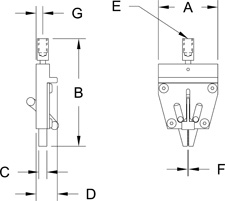

G1074 Vise Grip Standard |

|

|

This general purpose vise can be used in a wide range of tension and compression testing applications. Wide opening range accommodates large and unique samples. Rugged design permits testing up to 500 lbF (2,500 N).

The G1070 self-centering vise grip offers smooth removable jaws can be field-modified to improve sample gripping characteristics as required for pull testing applications (more info).

Use this grip with a choice of test stand and force gauge to create a complete testing system

FEATURES

- Maximum tension force: 500 lbF (2,500 N)

- Removable jaws

- Mounts directly to the following test stands: ESM, ESM303, ES30, TSC1000, TSF, TSFM500. Also compatible with ES10/ES20 when ordered with optional AC1060 mounting plate.

- Weight G1070: 5.85 lb [2.65 kg]

Weight G1074: 2.0 lb (1.0 kg)

SPECIFICATIONS

| Model |

G1074 |

| Price |

$351.50 |

| Weight |

2.0 lb (1.0 kg) |

| Maximum tension force |

500 lbF (2,500 N) |

| Mounts directly |

ESM, ESM303, ES30, TSC1000, TSF, TSFM500. Also compatible with ES10/ES20 when ordered with optional AC1060 mounting plate. |

G1070

| A |

B |

C |

D |

E |

F |

G |

H |

I |

| 3.78 [96.0 |

0.30 [7.6] |

2.76 [70.1] |

2.33 [59.2] |

2.00 [50.8] |

0 - 2.00 [0 - 50.8] |

1.12 [28.5] |

2.00 [50.8] |

2.00 [50.8] |

|

G1074

| A |

B |

C |

D |

E |

F |

G |

| 1.00 [25.4] |

0.50 [12.7] |

1.50 [38.1] |

2.00 [50.8] |

2.50 [63.5] |

0 - 1.50 [0 - 38.1] |

1.00 [25.4] |

|

|

Mark-10 G1003 Miniature Component Grip |

This slender grip is ideal for testing small and hard-to-reach parts, such as electronic mechanical components. Use this grip with a force gauge and test stand to create a complete testing system.

Capacity

(lb / N) |

Weight

(lb / kg) |

A |

B |

C |

D |

| 30 / 150 |

0.05 / 0.02 |

0.5 / 12.7 |

1.7 / 43.2 |

0.5 / 12.7 |

0-0.07 / 0-1.8 |

|

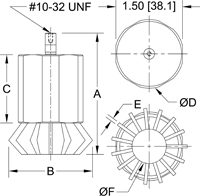

Mark-10 G1062 Miniature Wedge Grip |

This compact self-tightening grip with a capacity of 100 lb (500 N) is ideal for a range of low force tensile testing of small samples. The serrated steel jaws are easily opened with a spring-loaded lever.

- 100 lb [500 N] capacity

- Spring-loaded lever

- Serrated steel jaws

- Swiveling mounting attachment

- Thru slot for samples of unlimited width

- Weight: 0.08 lb [0.04 kg]

- Jaw material: 303 SS

| A |

B |

C |

D |

E |

F |

G |

| 1.37 [34.8] |

2.49 [63.1] |

0.19 [4.8] |

0.49 [12.4] |

#10-32 UNF |

0 - 0.16 [0 - 4.0] |

0.15 [3.9] |

|

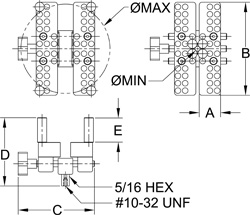

Mark-10 G1056 Multi-Jaw Grip |

This unique and universal grip is designed for gripping round and irregularly shaped items. Typical applications including pull-off tests of fasteners and components in the toy, clothing, and other industries

Adjustable jaws accommodate a range of sample shapes and sizes. Rotate the housing to open and close the jaws. |

Typical toy testing application |

| Cap. lb [N] |

Weight lb [kg] |

A |

B |

C |

ØD |

E |

ØF |

| 100 [500 N] |

0.30 [0.14] |

3.50 [88.9] |

2.30 [58.4] MAX |

1.63 [41.4] |

1.55 [39.4] |

0.075 [1.91] |

0.40 - 1.25 [10.2- 31.7] |

|

Mark 10 G1058 Universal Cap Grip |

This unique grip is designed to effectively secure samples for torque and pull tests. Typical applications include bottle cap torque testing, lid pull-off testing, and other tests. A matrix of threaded holes allows the serrated steel posts to be placed in positions specific to the test sample, with a broad diameter range of 0.2 - 3.5 in (5.1 - 89.0 mm).

For torque applications, this grip can be used either manually with an STJ torque sensor or MGT torque gauge, or in test stand controlled applications. A typical torque test stand-based application will also typically require our G1023 bottle grip. For force applications, the grip can be mounted to a force gauge or test stand.

The grip has a hex tail with internal thread to permit use in a chuck or for mounting to a force gauge or force test stand. An optional adapter is available to more securely mount the G1058 grip to the base of a force test stand.

Typical manual cap torque test using a Series STJ torque sensor |

G1058 is configured for a cap pull-off test using a force test stand |

Typical bottle cap torque test using a torque test stand |

| Cap. |

Weight lb [kg] |

A |

B |

C |

D |

E |

ØMIN - ØMAX |

| 100 lbin [11.3 Nm] or 50 lb [250 N] |

0.75 [0.34] |

0.9 [22.9] |

3.8 [96.5] |

3.2 [81.3] |

2.8 [71.1] |

1.0 [25.4] |

0.20 - 3.50[5.1 - 89.0] |

|

Mark-10 Padded Attachments |

|

These ergonomic padded attachments are designed for testing muscle strength and other job task requirements. They attach directly to Mark-10 force gauges

|

Mark-10 G1023 Bottle Grip |

|

This unique grip is designed for securing bottles, containers, and other items for closure torque testing. Eight rubber edged gripping arms effectively grip a wide range of sample shapes and sizes and can be individually positioned at angles of up to 180°. The G1023 mounts directly to the Mark-10 TST, TSTH, TSTM, and TSTMH Torque Measurement Test Stands. The grip may also be mounted to a force measurement stand to secure closures in such applications as top load testing.

100 / 11.3 |

1.5 / 0.7 |

4.8 / 122.0 max |

|

|

|

This grip effectively secures bottle caps during torque testing. The G1053 is designed with a hex tail to fit into the chucks of our torque sensors. Reversible serrated jaws accommodate caps with diameters of 0.65 - 1.80 in [16.5 - 45.7 mm] while a knob quickly engages and disengages samples.

This grip can be used either manually with an STJ torque sensor or MGT torque gauge (see application photo at left), or in test stand controlled applications, using our Series TST torque test stands. If used with a test stand, this grip complements our G1023 bottle grip.

| Capacity (lb-in / N-m) |

Weight (lb / kg) |

A |

B |

C |

D1* |

D2* |

100 / 11.3 |

0.39 / 0.18 |

3.1 / 78.7 |

2.0 / 50.8 |

1.6 / 40.6 |

1.16-1.8 / 29.5-45.7 |

0.65-1.29 / 16.5-32.8 |

* Jaws must be reversed to switch from ØD1 to ØD2

|

Mark-10 G1022 Jacobs Chuck Grip for TSTM |

|

These grips are designed for gripping samples during torque testing, for use with TST, TSTH, TSTM, and TSTMH Torque Measurement Test Stands. Available in three chuck capacities. Includes key.

| Model |

Capacity (lb-in / N-m) |

Weight (lb / kg) |

B |

C |

| G1022-1 |

100 / 11.3 |

0.5 / 0.23 |

0.188 / 4.7 |

0.028-0.25 / 0.7-6.3 |

| G1022-2 |

0.062-0.375 / 1.6-9.5 |

| G1022-3 |

0.078-0.5 / 2-12.7 |

|

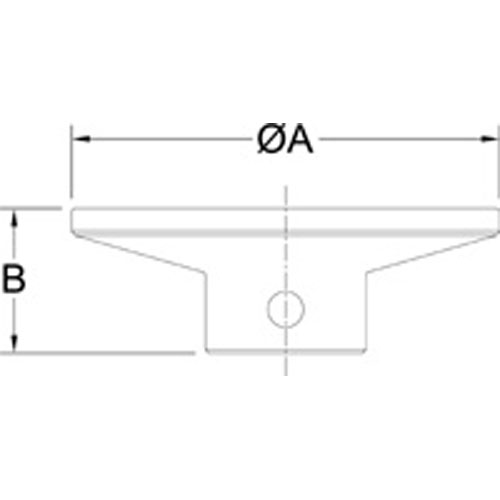

Mark-10 G1009 Compression Plates |

G1009 |

G1087 |

|

|

G1009 These aluminum compression plates are ideal for testing springs, foams, and other materials. The plates attach directly to Mark-10 force gauges and test stands.

G1087 These Stainless Steel plates feature integrated eye ends, and require eye end adapters to mount to Mark-10 force gauges, load cells, and test stands |

G1009

|

G1087

|

| Model |

Capacity (lb / N) |

Weight (lb / kg) |

A |

B |

| G1009 |

200 lb / 1000 N |

0.08 lb / 0.04 kg |

2.0 in / 51.0 mm |

|

| G1009-1 |

500 lb / 2500 N |

0.27 lb / 0.12 kg |

3.0 in / 76.2 mm |

|

| G1087 |

2000 lb / 9000 N |

1.50 lb / 0.68 kg |

3.78 in / 96.0 mm |

1.28 in / 32.5 mm |

| G1087-1 |

2000 lb / 9000 N |

0.63 lb / 0.29 kg |

2.20 in / 55.9 mm |

1.18 in / 30.0 mm |

|

Mark-10 G1098 ASTM D6195 Loop Tack Fixture |

|

Designed for tack force testing of pressure-sensitive adhesives, in conformance with ASTM D6195 and related standards. A looped sample is loaded onto the test strip, and the closed end of the loop is secured by an upper grip (not included - suggested model: G1008). The test strip may be indexed in three positions, allowing for three tests to be performed between cleaning cycles. The strip is secured and released by a lever-operated clamp. An additional set of three test strips is available.

SPECIFICATIONS

Capacity

lbF [N] |

Weight*

lb [kg] |

Test strip material |

| 100 [500] |

1.10 [0.5] |

T304 SS, per ASTM A666 |

* including one test strip

|